UL Certificated for transformer enameled coated aluminium winding wire

Basic Info

Model No.: winding wire

Product Description

UL Certificated for transformer enameled coated aluminium winding wire 1.Process of producing We can producing all the sizes in following :

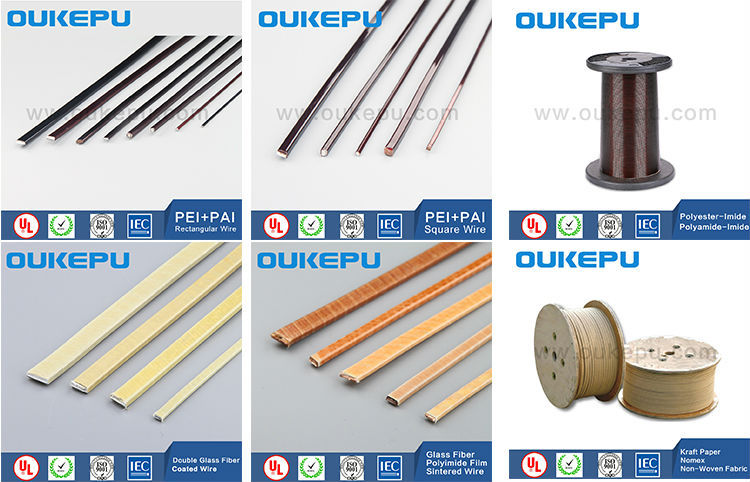

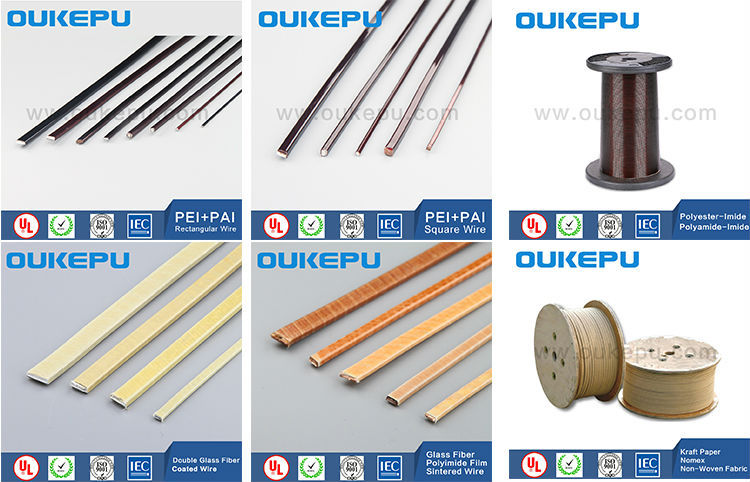

More products

More products  Test equipment ouwei electric has a professional team to guarantee quality . 2. Process of Producing & Testing Maximum Overall Diameter, Conductor Diameter, Film Thickness, Conductor Resistance, Elongation, Spring Back, Mandrel Winding, Sudden Jerk, Cut Through, Heat Shock, Room Temperature Breakdown Voltage, High Voltage Hole, and Pin-Hole, etc.

Test equipment ouwei electric has a professional team to guarantee quality . 2. Process of Producing & Testing Maximum Overall Diameter, Conductor Diameter, Film Thickness, Conductor Resistance, Elongation, Spring Back, Mandrel Winding, Sudden Jerk, Cut Through, Heat Shock, Room Temperature Breakdown Voltage, High Voltage Hole, and Pin-Hole, etc.

Company Information Factory Figures: No. of Employees: 400, including 22 Senior Engineers Workshops: 27,000.00m2 in area included Oxygen-Free Copper and Aluminum Rod Workshop, Continuous Extrusion Workshop, Wire Drawing Workshop, etc. Equipments: 76 Sets included Continuous Extrusion, Enameled Production Line, continuous enameled production line, polyester glass sintering line, package production line and sintered polyimide film production line. Production Capacity: 1500MT/month .

Company Information Factory Figures: No. of Employees: 400, including 22 Senior Engineers Workshops: 27,000.00m2 in area included Oxygen-Free Copper and Aluminum Rod Workshop, Continuous Extrusion Workshop, Wire Drawing Workshop, etc. Equipments: 76 Sets included Continuous Extrusion, Enameled Production Line, continuous enameled production line, polyester glass sintering line, package production line and sintered polyimide film production line. Production Capacity: 1500MT/month .

3.Insulating Varnish for our enameled wire to guarantee quality. ELANTAS Electrical Insulation are enamels used for manufacturing of magnet wires. They are coated on the surface of copper or alumina wires and cured to form electrical insulation film possessing certain mechanical strength, thermal resistant and chemical resistant properties. Some products could be used for other applications such as metal wires for decoration purpose and other insulating or thermal resistant coatings. Our products are classified in the following categories based on main polymers and applications: 1.Polyvinylformal Enamels 2.Polyurethane Enamels 3.Polyesterimide Solderable Enamels 4.Polyesterimide Enamels 5.Polyester Enamels 6.Polyamideimide Enamels 7.Polyimide Enamels 8.Nylon Enamels 9.Bondable Enamel

3.Insulating Varnish for our enameled wire to guarantee quality. ELANTAS Electrical Insulation are enamels used for manufacturing of magnet wires. They are coated on the surface of copper or alumina wires and cured to form electrical insulation film possessing certain mechanical strength, thermal resistant and chemical resistant properties. Some products could be used for other applications such as metal wires for decoration purpose and other insulating or thermal resistant coatings. Our products are classified in the following categories based on main polymers and applications: 1.Polyvinylformal Enamels 2.Polyurethane Enamels 3.Polyesterimide Solderable Enamels 4.Polyesterimide Enamels 5.Polyester Enamels 6.Polyamideimide Enamels 7.Polyimide Enamels 8.Nylon Enamels 9.Bondable Enamel  4. Application field: Suitable for winding coils of oil-immersed transformers, dry-type transformers, high-temperature transformers, and wide range of motors.

4. Application field: Suitable for winding coils of oil-immersed transformers, dry-type transformers, high-temperature transformers, and wide range of motors.  Packaging & Shipping Inner packing: in different plastic spools(Plastic Spool of ,PT-60 and PT-90), PT-15,PT-25) Outer packing:wooden pallet with steel strip or according customers' special requirements 5. Packing: Inner packing: in different plastic spools(Plastic Spool of ,PT-60 ,PT-90,PT-25 and PT-28) Outer packing:wooden pallet with paper board and stretch film Or according customers' special requirements

Packaging & Shipping Inner packing: in different plastic spools(Plastic Spool of ,PT-60 and PT-90), PT-15,PT-25) Outer packing:wooden pallet with steel strip or according customers' special requirements 5. Packing: Inner packing: in different plastic spools(Plastic Spool of ,PT-60 ,PT-90,PT-25 and PT-28) Outer packing:wooden pallet with paper board and stretch film Or according customers' special requirements  Our Services

Our Services  8.Our products export many countries

8.Our products export many countries  FAQ Q: Are you a manufacturer or a trading company ? A: We are a professional manufacturer of enameled wire for rewinding in China . Q: how about your company’s annual production capacity? A: Our Company’s annual production are 1200ton/month. Q: How large the scale of your company? A: Our Company covers almost 2,700,000 square meters.and 76 sets included continuous extrusion. Q: How many kind of spools size ? A:PT4, PT10, PT15, PT25, PT35, PT60, PT90, wooden spools PT-500 and etc. Q : What is specifications of enameled wire your company can produce? A: 1.Enameled round wire: 0.10mm-6.00mm 2.Enameled Rectangular Wire: Side(a): 1mm-10mm, Side(b): 2mm-16mm 3.Enameled Square Wire:1.00mm-8.00mm 4.Kraft paper covered round wire: 1.5mm-5.0mm 5.Kraft paper covered ractangular wire: (a)1.0mm-5.6mm, (b) 2.00-16mm 6.Fiberglass covered round wire:1.00mm-8.00mm 7.Fiberglass covered rectangular wire:(a)1.00mm-5.60mm,(b)2.00mm-16.00mm Q : What’s the temperature-resist grade of your enameled wire? A: We produce the thermal class of enameled wire from class130 to class220 Contact us if you need more details on Enameled Aluminum Flat Wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminium Winding Wire、Enameled Aluminum Wire. If these products fail to match your need, please contact us and we would like to provide relevant information.

FAQ Q: Are you a manufacturer or a trading company ? A: We are a professional manufacturer of enameled wire for rewinding in China . Q: how about your company’s annual production capacity? A: Our Company’s annual production are 1200ton/month. Q: How large the scale of your company? A: Our Company covers almost 2,700,000 square meters.and 76 sets included continuous extrusion. Q: How many kind of spools size ? A:PT4, PT10, PT15, PT25, PT35, PT60, PT90, wooden spools PT-500 and etc. Q : What is specifications of enameled wire your company can produce? A: 1.Enameled round wire: 0.10mm-6.00mm 2.Enameled Rectangular Wire: Side(a): 1mm-10mm, Side(b): 2mm-16mm 3.Enameled Square Wire:1.00mm-8.00mm 4.Kraft paper covered round wire: 1.5mm-5.0mm 5.Kraft paper covered ractangular wire: (a)1.0mm-5.6mm, (b) 2.00-16mm 6.Fiberglass covered round wire:1.00mm-8.00mm 7.Fiberglass covered rectangular wire:(a)1.00mm-5.60mm,(b)2.00mm-16.00mm Q : What’s the temperature-resist grade of your enameled wire? A: We produce the thermal class of enameled wire from class130 to class220 Contact us if you need more details on Enameled Aluminum Flat Wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminium Winding Wire、Enameled Aluminum Wire. If these products fail to match your need, please contact us and we would like to provide relevant information.

| Enameled round aluminum wire

| Enameled flat aluminum wire

|

| Enameled round copper wire

| Enameled flat copper wire

|

| Non Woven Cloth/ Polyester Film covered wire

| Polyimide Film Wrapped wire

|

| Film Wrapped Enameled Wire

| NOMEX Paper covered wire

|

| fiberglass Film Wrapped wire

|

|

More products

More products  Test equipment ouwei electric has a professional team to guarantee quality . 2. Process of Producing & Testing Maximum Overall Diameter, Conductor Diameter, Film Thickness, Conductor Resistance, Elongation, Spring Back, Mandrel Winding, Sudden Jerk, Cut Through, Heat Shock, Room Temperature Breakdown Voltage, High Voltage Hole, and Pin-Hole, etc.

Test equipment ouwei electric has a professional team to guarantee quality . 2. Process of Producing & Testing Maximum Overall Diameter, Conductor Diameter, Film Thickness, Conductor Resistance, Elongation, Spring Back, Mandrel Winding, Sudden Jerk, Cut Through, Heat Shock, Room Temperature Breakdown Voltage, High Voltage Hole, and Pin-Hole, etc. | Code Number | Test Standard | GB/T23312-7-2009 | |

| Size | 2.0mm | Date | |

| Type Q(ZY/XY)L-240 polyesterimide coated with polyamideimide | |||

| Test Tens | Standard value | Test Result | |

| Size | Maximum | 2.112mm | 2.095mm |

| Conductor Diameter | 2.00mm | 2.012mm | |

| Tolerance Value | ±0.020mm | 0.012mm | |

| F Result | ≤0.020mm | 0.001mm | |

| Film Thickness | ≥0.075mm | 0.083mm | |

| 20°C Resistivity | 0.008698-0.009149Ω/m | 0.00903-Ω/m | |

| Elongation | ≥15% | 32.20% | |

| Adherence | Test Axis Around | Winding ID | OK |

| Flexibility | Sudden/Pull | ≥55R | 65R |

| Anti-Solvent | ≥1h | 2h | |

| Alt-Throngh | 320°C,2min | OK | |

| Hot Shock | 240°C,30min | OK | |

| Broken Down Voltage Will Room | ≥5.0KV | 11.3/9.7/12/11.5/kv | |

| Continuity | High Voltage Hole | / | / |

| Pin-Hole | ≤5pcs/6m | 1pcs | |

| Conculusion | OK | ||

Company Information Factory Figures: No. of Employees: 400, including 22 Senior Engineers Workshops: 27,000.00m2 in area included Oxygen-Free Copper and Aluminum Rod Workshop, Continuous Extrusion Workshop, Wire Drawing Workshop, etc. Equipments: 76 Sets included Continuous Extrusion, Enameled Production Line, continuous enameled production line, polyester glass sintering line, package production line and sintered polyimide film production line. Production Capacity: 1500MT/month .

Company Information Factory Figures: No. of Employees: 400, including 22 Senior Engineers Workshops: 27,000.00m2 in area included Oxygen-Free Copper and Aluminum Rod Workshop, Continuous Extrusion Workshop, Wire Drawing Workshop, etc. Equipments: 76 Sets included Continuous Extrusion, Enameled Production Line, continuous enameled production line, polyester glass sintering line, package production line and sintered polyimide film production line. Production Capacity: 1500MT/month .

3.Insulating Varnish for our enameled wire to guarantee quality. ELANTAS Electrical Insulation are enamels used for manufacturing of magnet wires. They are coated on the surface of copper or alumina wires and cured to form electrical insulation film possessing certain mechanical strength, thermal resistant and chemical resistant properties. Some products could be used for other applications such as metal wires for decoration purpose and other insulating or thermal resistant coatings. Our products are classified in the following categories based on main polymers and applications: 1.Polyvinylformal Enamels 2.Polyurethane Enamels 3.Polyesterimide Solderable Enamels 4.Polyesterimide Enamels 5.Polyester Enamels 6.Polyamideimide Enamels 7.Polyimide Enamels 8.Nylon Enamels 9.Bondable Enamel

3.Insulating Varnish for our enameled wire to guarantee quality. ELANTAS Electrical Insulation are enamels used for manufacturing of magnet wires. They are coated on the surface of copper or alumina wires and cured to form electrical insulation film possessing certain mechanical strength, thermal resistant and chemical resistant properties. Some products could be used for other applications such as metal wires for decoration purpose and other insulating or thermal resistant coatings. Our products are classified in the following categories based on main polymers and applications: 1.Polyvinylformal Enamels 2.Polyurethane Enamels 3.Polyesterimide Solderable Enamels 4.Polyesterimide Enamels 5.Polyester Enamels 6.Polyamideimide Enamels 7.Polyimide Enamels 8.Nylon Enamels 9.Bondable Enamel  4. Application field: Suitable for winding coils of oil-immersed transformers, dry-type transformers, high-temperature transformers, and wide range of motors.

4. Application field: Suitable for winding coils of oil-immersed transformers, dry-type transformers, high-temperature transformers, and wide range of motors.  Packaging & Shipping Inner packing: in different plastic spools(Plastic Spool of ,PT-60 and PT-90), PT-15,PT-25) Outer packing:wooden pallet with steel strip or according customers' special requirements 5. Packing: Inner packing: in different plastic spools(Plastic Spool of ,PT-60 ,PT-90,PT-25 and PT-28) Outer packing:wooden pallet with paper board and stretch film Or according customers' special requirements

Packaging & Shipping Inner packing: in different plastic spools(Plastic Spool of ,PT-60 and PT-90), PT-15,PT-25) Outer packing:wooden pallet with steel strip or according customers' special requirements 5. Packing: Inner packing: in different plastic spools(Plastic Spool of ,PT-60 ,PT-90,PT-25 and PT-28) Outer packing:wooden pallet with paper board and stretch film Or according customers' special requirements  Our Services

Our Services  8.Our products export many countries

8.Our products export many countries  FAQ Q: Are you a manufacturer or a trading company ? A: We are a professional manufacturer of enameled wire for rewinding in China . Q: how about your company’s annual production capacity? A: Our Company’s annual production are 1200ton/month. Q: How large the scale of your company? A: Our Company covers almost 2,700,000 square meters.and 76 sets included continuous extrusion. Q: How many kind of spools size ? A:PT4, PT10, PT15, PT25, PT35, PT60, PT90, wooden spools PT-500 and etc. Q : What is specifications of enameled wire your company can produce? A: 1.Enameled round wire: 0.10mm-6.00mm 2.Enameled Rectangular Wire: Side(a): 1mm-10mm, Side(b): 2mm-16mm 3.Enameled Square Wire:1.00mm-8.00mm 4.Kraft paper covered round wire: 1.5mm-5.0mm 5.Kraft paper covered ractangular wire: (a)1.0mm-5.6mm, (b) 2.00-16mm 6.Fiberglass covered round wire:1.00mm-8.00mm 7.Fiberglass covered rectangular wire:(a)1.00mm-5.60mm,(b)2.00mm-16.00mm Q : What’s the temperature-resist grade of your enameled wire? A: We produce the thermal class of enameled wire from class130 to class220 Contact us if you need more details on Enameled Aluminum Flat Wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminium Winding Wire、Enameled Aluminum Wire. If these products fail to match your need, please contact us and we would like to provide relevant information.

FAQ Q: Are you a manufacturer or a trading company ? A: We are a professional manufacturer of enameled wire for rewinding in China . Q: how about your company’s annual production capacity? A: Our Company’s annual production are 1200ton/month. Q: How large the scale of your company? A: Our Company covers almost 2,700,000 square meters.and 76 sets included continuous extrusion. Q: How many kind of spools size ? A:PT4, PT10, PT15, PT25, PT35, PT60, PT90, wooden spools PT-500 and etc. Q : What is specifications of enameled wire your company can produce? A: 1.Enameled round wire: 0.10mm-6.00mm 2.Enameled Rectangular Wire: Side(a): 1mm-10mm, Side(b): 2mm-16mm 3.Enameled Square Wire:1.00mm-8.00mm 4.Kraft paper covered round wire: 1.5mm-5.0mm 5.Kraft paper covered ractangular wire: (a)1.0mm-5.6mm, (b) 2.00-16mm 6.Fiberglass covered round wire:1.00mm-8.00mm 7.Fiberglass covered rectangular wire:(a)1.00mm-5.60mm,(b)2.00mm-16.00mm Q : What’s the temperature-resist grade of your enameled wire? A: We produce the thermal class of enameled wire from class130 to class220 Contact us if you need more details on Enameled Aluminum Flat Wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminium Winding Wire、Enameled Aluminum Wire. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Enameled Round aluminium(copper) wire

Premium Related Products

Other Products

Hot Products

Zinc-5%Aluminum-Mischmetal Alloy-Coated Steel WireISO 6934-4: 1991, Steel Strand Wire for The Prestressing of ConcreteHigh Quality Crimped Wire MeshSpring Steel Wire for Spring, Furniture, DecorationAluminum Clad Steel Wire Aluminum Single WireGalvanized Steel Wire Galvanized WireCopper Clad Aluminum Wire Copper Wire CCA Wirecrepe paper tube/crinkled insulating paper tubeTransformer Duct stripzhejiang factory China transformer partners varnish aluminum square wirepaper covered magnet wire,paper covered winding wire,Cotton cloth covered wireFlange Type Transformer Radiator,transformer radiator fin,transformer radiator fin180C degree 0.40mm thichness double glass fiber covered aluminum wire,glassfiber wire with enamelledhigh shock voltage 180C degree Flat enameled aluminum wire suppliersHeat shock no cracks EI/AIW 200C aluminum Enameled flat wireexporter of polyester super Enameled aluminum wire