paint removing/UEW class220 enamelled aluminum electromagnet winding wire

Basic Info

Model No.: Enamelled wire

Product Description

UL approved colored red color round Enameled aluminum magnet wire Product Description

Advantage 1.Ouwei factory Established in 2003, Located in zhejiang province,,China is a professional manufacturer of Enameled Wire . 2.Factory Figures: No. of Employees: 400, including 22 Senior Engineers Workshops: 27,000.00m2 in area included Oxygen-Free Copper and Aluminum Rod Workshop, Continuous Extrusion Workshop, Wire Drawing Workshop, etc Equipments: 76 Sets included Continuous Extrusion, Enameled Production Line, continuous enameled production line, polyester glass sintering line, package production line and sintered polyimide film production line. Production Capacity: 1500MT/month . Application Specification Standards 1. IEC,ISO Specification 2. International/Customised Standard Applications ELECTRICAL MOTORS LIGHTING FIXTURES TRANSFORMERS COILS SWITCHGEAR SOLONOID VALVES AUTOMOBILES ELECTRICAL APPLIANCES INDUSTRIAL ELECTRONICS PUMPS&FANS WORKSHOP DETAILS

Advantage 1.Ouwei factory Established in 2003, Located in zhejiang province,,China is a professional manufacturer of Enameled Wire . 2.Factory Figures: No. of Employees: 400, including 22 Senior Engineers Workshops: 27,000.00m2 in area included Oxygen-Free Copper and Aluminum Rod Workshop, Continuous Extrusion Workshop, Wire Drawing Workshop, etc Equipments: 76 Sets included Continuous Extrusion, Enameled Production Line, continuous enameled production line, polyester glass sintering line, package production line and sintered polyimide film production line. Production Capacity: 1500MT/month . Application Specification Standards 1. IEC,ISO Specification 2. International/Customised Standard Applications ELECTRICAL MOTORS LIGHTING FIXTURES TRANSFORMERS COILS SWITCHGEAR SOLONOID VALVES AUTOMOBILES ELECTRICAL APPLIANCES INDUSTRIAL ELECTRONICS PUMPS&FANS WORKSHOP DETAILS

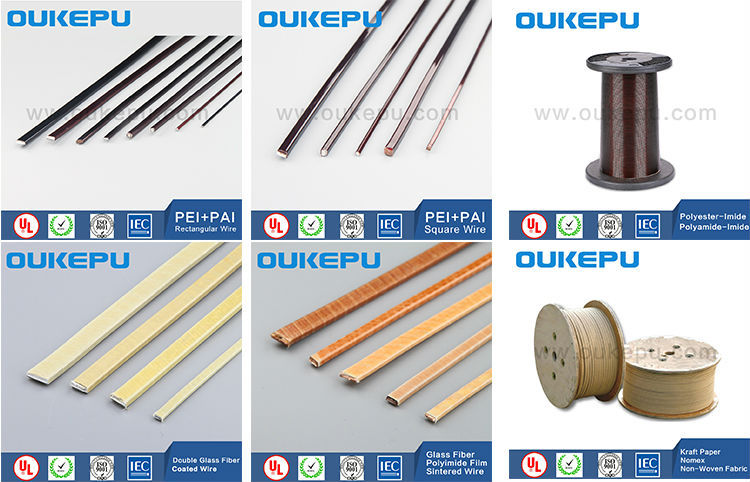

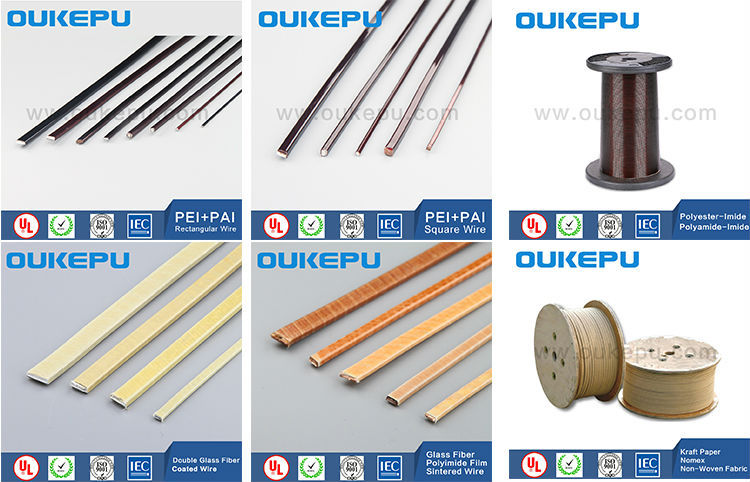

More products

More products  Process of Producing & Testing Maximum Overall Diameter, Conductor Diameter, Film Thickness, Conductor Resistance, Elongation, Spring Back, Mandrel Winding, Sudden Jerk, Cut Through, Heat Shock, Room Temperature Breakdown Voltage, High Voltage Hole, and Pin-Hole, etc.

Process of Producing & Testing Maximum Overall Diameter, Conductor Diameter, Film Thickness, Conductor Resistance, Elongation, Spring Back, Mandrel Winding, Sudden Jerk, Cut Through, Heat Shock, Room Temperature Breakdown Voltage, High Voltage Hole, and Pin-Hole, etc.

Packaging & Shipping Packing Details PT6 ,PT10 ,PT25 ,PT30,PT45,LPT60 ,Pt90 Pt190 & as per Customers Requirements Round size Rectangular size,Square size

Rectangular size,Square size  Contact us if you need more details on Winding Wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Electromagnet Winding Wire、Aluminum Electromagnet Winding Wire. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Winding Wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Electromagnet Winding Wire、Aluminum Electromagnet Winding Wire. If these products fail to match your need, please contact us and we would like to provide relevant information.

| Product Range | Thermal class | Specification |

| Polyester | 130 C | IS-13730-Part-34 |

| Modified Polyester Enamelled | 155 C | IS-13730-Part-3 |

| Polyestermide | 180 C | IS-13730-Part-08 |

| Polyimide imide | 200 C/220C | IS-13730-Part-13 |

| Self Solderable | 155 C & 180 C | IS-13730-Part-20 & 23 |

Advantage 1.Ouwei factory Established in 2003, Located in zhejiang province,,China is a professional manufacturer of Enameled Wire . 2.Factory Figures: No. of Employees: 400, including 22 Senior Engineers Workshops: 27,000.00m2 in area included Oxygen-Free Copper and Aluminum Rod Workshop, Continuous Extrusion Workshop, Wire Drawing Workshop, etc Equipments: 76 Sets included Continuous Extrusion, Enameled Production Line, continuous enameled production line, polyester glass sintering line, package production line and sintered polyimide film production line. Production Capacity: 1500MT/month . Application Specification Standards 1. IEC,ISO Specification 2. International/Customised Standard Applications ELECTRICAL MOTORS LIGHTING FIXTURES TRANSFORMERS COILS SWITCHGEAR SOLONOID VALVES AUTOMOBILES ELECTRICAL APPLIANCES INDUSTRIAL ELECTRONICS PUMPS&FANS WORKSHOP DETAILS

Advantage 1.Ouwei factory Established in 2003, Located in zhejiang province,,China is a professional manufacturer of Enameled Wire . 2.Factory Figures: No. of Employees: 400, including 22 Senior Engineers Workshops: 27,000.00m2 in area included Oxygen-Free Copper and Aluminum Rod Workshop, Continuous Extrusion Workshop, Wire Drawing Workshop, etc Equipments: 76 Sets included Continuous Extrusion, Enameled Production Line, continuous enameled production line, polyester glass sintering line, package production line and sintered polyimide film production line. Production Capacity: 1500MT/month . Application Specification Standards 1. IEC,ISO Specification 2. International/Customised Standard Applications ELECTRICAL MOTORS LIGHTING FIXTURES TRANSFORMERS COILS SWITCHGEAR SOLONOID VALVES AUTOMOBILES ELECTRICAL APPLIANCES INDUSTRIAL ELECTRONICS PUMPS&FANS WORKSHOP DETAILS

More products

More products  Process of Producing & Testing Maximum Overall Diameter, Conductor Diameter, Film Thickness, Conductor Resistance, Elongation, Spring Back, Mandrel Winding, Sudden Jerk, Cut Through, Heat Shock, Room Temperature Breakdown Voltage, High Voltage Hole, and Pin-Hole, etc.

Process of Producing & Testing Maximum Overall Diameter, Conductor Diameter, Film Thickness, Conductor Resistance, Elongation, Spring Back, Mandrel Winding, Sudden Jerk, Cut Through, Heat Shock, Room Temperature Breakdown Voltage, High Voltage Hole, and Pin-Hole, etc. | Code Number | Test Standard | GB/T23312-7-2009 | |

| Size | 2.0mm | Date | |

| Type Q(ZY/XY)L-240 polyesterimide coated with polyamideimide | |||

| Test Tens | Standard value | Test Result | |

| Size | Maximum | 2.112mm | 2.095mm |

| Conductor Diameter | 2.00mm | 2.012mm | |

| Tolerance Value | ±0.020mm | 0.012mm | |

| F Result | ≤0.020mm | 0.001mm | |

| Film Thickness | ≥0.075mm | 0.083mm | |

| 20°C Resistivity | 0.008698-0.009149Ω/m | 0.00903-Ω/m | |

| Elongation | ≥15% | 32.20% | |

| Adherence | Test Axis Around | Winding ID | OK |

| Flexibility | Sudden/Pull | ≥55R | 65R |

| Anti-Solvent | ≥1h | 2h | |

| Alt-Throngh | 320°C,2min | OK | |

| Hot Shock | 240°C,30min | OK | |

| Broken Down Voltage Will Room | ≥5.0KV | 11.3/9.7/12/11.5/kv | |

| Continuity | High Voltage Hole | / | / |

| Pin-Hole | ≤5pcs/6m | 1pcs | |

| Conculusion | OK | ||

Rectangular size,Square size

Rectangular size,Square size  Contact us if you need more details on Winding Wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Electromagnet Winding Wire、Aluminum Electromagnet Winding Wire. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Winding Wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Electromagnet Winding Wire、Aluminum Electromagnet Winding Wire. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Enameled Round aluminium(copper) wire

Premium Related Products

Other Products

Hot Products

Zinc-5%Aluminum-Mischmetal Alloy-Coated Steel WireISO 6934-4: 1991, Steel Strand Wire for The Prestressing of ConcreteHigh Quality Crimped Wire MeshSpring Steel Wire for Spring, Furniture, DecorationAluminum Clad Steel Wire Aluminum Single WireGalvanized Steel Wire Galvanized WireCopper Clad Aluminum Wire Copper Wire CCA Wirecrepe paper tube/crinkled insulating paper tubeTransformer Duct stripzhejiang factory China transformer partners varnish aluminum square wirepaper covered magnet wire,paper covered winding wire,Cotton cloth covered wireFlange Type Transformer Radiator,transformer radiator fin,transformer radiator fin180C degree 0.40mm thichness double glass fiber covered aluminum wire,glassfiber wire with enamelledhigh shock voltage 180C degree Flat enameled aluminum wire suppliersHeat shock no cracks EI/AIW 200C aluminum Enameled flat wireexporter of polyester super Enameled aluminum wire